To learn more about the flex Hone Tools, view the PDF catalogues below:

Flex Hone brochure here.

Flex Hone Introduction

Hydraulic Torque Wrenches - Sq Dr.

Hydraulic Torque Wrenches - Hex

Pneumatic Nut-runners

Porta Power

Impact Guns

Impact Sockets

Hire Torque Tools

Pumps and Hoses

Hire

Contact us

What are Flex Hone Tools?

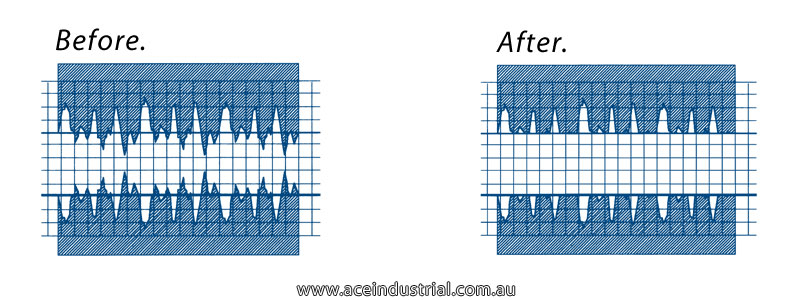

The Flex Hone Tool removes peaks and other imperfections in cylinder walls to create a smoother and safer finsh. The result is reduced friction and therefore improved performance and minimal chance of damage. The Flex-Hone tool was originally created by BRM to deglaze cylinder walls in automotive applications. Brush Research embraced the benefits of a plateau finish and pioneered the concept of plateau honing culminating in the introduction of the Flex-Hone tool in 1972. The Flex-Hone® has gained many nicknames over the years and including ball hone, ball style hone, flexihone, dingleberry hone, bead brush, glaze breaker and glaze buster. Flexible honing with the Flex-Hone® tool produces an oil holding cross hatch pattern and a true plateau finish free of cut, torn and folded metal. Any type or size of cylinder can benefit from the Flex-Hone®.

These abrasive bead style brushes are produced in standard diameters from 4mm to 36”. Eight abrasive types are offered including silicon carbide, aluminum oxide, boron carbide and diamond allowing the tool to be tailored to finish any base material. A choice of 11 different grit selections are available for precise control of finish parameters.

The elimination of peaks results in rapid ring seating, better oil control, reduced seepage in hydraulic and pneumatic applications and provides better seal performance and longer seal life. Successful applications include firearm chambers, shotgun barrels, musical instruments, combustion chambers, air compressors, pumps, valve bodies, valve guides, brake cylinders, wheel cylinders and the list goes on and on.

Before and After examples of the flex hone tool effect.

The tool can be run from 60 to 1200 RPM, depending on tool diameter. The smaller the diameter, the higher the spindle speeds. Start with a spindle speed between 500-800RPM. You may need to experiment to find the optimum speed for your application. Never exceed 1200 RPM. The Flex-Hone tool must always be used with a good quality cutting oil or honing fluid to keep heat to a minimum, prevent the tool from loading and to suspend the material being removed.

The Flex-Hone tool should have a continuous stroke rate between 120 to 180 inches per minute. Final stroking may be accelerated to develop a 45° crosshatch finish. Use the minimum honing time needed to achieve the required finish. Average honing time is 10-25 seconds, (5-15 strokes). Clean the cylinder using hot, soapy water and brush the cylinder wall with a cleaning brush. Dry the cylinder and continue to clean with a lint free cloth coated with a light oil or mineral spirits. Continue to clean until the lint free cloth remains clean.

Flex Hone for Rotors

Brush Research Manufacturing is proud to offer the Flex-Hone for Rotors. This unique tool utilizes the patented Flex-Hone® technology to produce the ideal surface finish on disc brake rotors and flywheels. The Flex-Hone for Rotors benefits include: completion of more rotors per hone, produces a non-directional pattern, lowers harmonic vibrations eliminating annoying brake noise, and is ideal for new or re-turned rotors and flywheels. View the PDF on Flex Hone for rotors Here.

To view this information in much more detail, please view the official Flex Hone brochure here.

Ace Industrial Distributors are proud to offer quality and renowned products such as: Rapidtorc Hydraulic Torque Wrenches, Action Impact Sockets, Momento Impact Sockets, Ingersoll Rand Impact Guns, Chicago Pneumatic impact guns, Powerteam jacking rams and hand pumps.

Specializing to heavy industry, Ace Industrial Distributors offer unique solutions for torque and Impact, suited to any variety of jobs.

We are sure you have questions, answers and solutions are only a phone call away. Click here for contact details.

We look forward to hearing from you, and thank you for visiting our web site.